Roof Construction

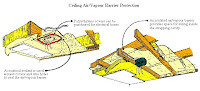

Most homes built in cold climates have a sloped roof surface while the interior ceiling can reflect the roof slope, follow a different slope, or can be flat. Because heated air does tend to rise, the recommended insulation levels for ceilings is usually higher than for walls. A complete, well-sealed air/vapour barrier is essential at the ceiling level, but because of light fixtures, plumbing vents and chimneys, can be difficult to install. The air/vapour barrier must be sealed around the potential 'holes' in a ceiling, regardless of the type of roof or ceiling construction. The obvious first step in design is to eliminate as many of these potential problems as possible before they occur in construction.

Air Sealing

The electrical wiring, the various junction boxes, and ceiling outlets create numerous opportunities for breaks in an otherwise continuous ceiling air/vapour barrier. Much can be done to eliminate some of these potential breaks. Using interior wall-mounted fixtures are examples of alternatives. If wiring and outlets are required in the ceiling, using special polyethylene air/vapour boxes or isolating the air/vapour barrier are methods which can be used to maintain the continuity of the air/vapour barrier.

Ceiling mounted exhaust fan installations also cause problems. Firstly, because of the difficulty in sealing around them and secondly because the built-in dampers do not seal well and let warm air leak out. They usually vent through the attic so leaking warm air can cause condensation problems.

If possible, exhaust fans should only be installed on interior walls with ducts routed down the wall and out the floor joist space. This prevents cold air from infiltrating in through the duct pipes.

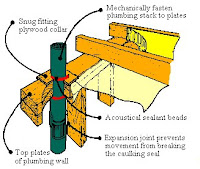

Plumbing stacks and chimneys are necessary 'punctures' in the ceiling of a home. The ceiling air/vapour barrier can be well sealed to plumbing stacks and vents but the pipes must be securely fastened so that expansion and contraction does not break the seal. An expansion joint, placed in the warm interior, can accommodate pipe movement so that it does not affect the ceiling joint.

Sealing Plumbing Stacks and Chimneys

Metal firestops, properly insulated and sealed are needed to control air leakage around chimneys. Again, by making the proper design decisions, the number of stacks, vents and chimneys may be reduced.

Many homes have an exterior door in their ceiling - an attic access hatch. It is best if the hatch is eliminated from the interior and placed on an outside gable end or through an unheated garage if possible. If not, make sure that the attic hatch door is well insulated, weatherstripped and secured to eliminate air leakage and heat loss.

Roofs and Ceilings

Flat Ceilings

The use of flat ceilings and truss rafters is a common North American building practice. This type of construction leaves an adequate depth in the attic space for loose fill or batt insulation except at the edge over the exterior walls. Modified types of truss rafters can be used to increase the depth at this point.

Maintaining adequate attic ventilation is important. For every 300 ft² of ceiling area, there must be 1 ft² of free ventilation area provided by soffit and roof or gable end vents (a 300:1 ratio - 300 m² of ceiling area vented by 1 m² of vent). This ventilation ensures any water vapour that does find its way above the insulation will be carried out of the space.

Using truss rafters allows the ceiling air/vapour barrier to be installed in one piece. Because the trusses span from exterior wall to exterior wall, the interior partitions can be installed after the ceiling is sealed and covered. However, if partitions must be installed before the ceiling polyethylene is applied, an extra air/vapour barrier strip has to be added to maintain continuity. Any joints must be sealed and must occur over solid backing such as ceiling joists or partition wall top plates. Isolating the air/vapour barrier with strapping is an option which provides protection against tears and provides a space for electrical wiring installation.

Sloped Ceilings

There are three methods of building well-insulated and sealed sloped ceilings. One method is to incorporate a wide joist or flat truss which will leave sufficient space for the insulation and ventilation.

Sloped Truss Ceilings

Another method used for sloped ceilings is to use a scissor truss, which has a flatter bottom slope than top. This type of ceiling is then insulated and sealed in the same method as was discussed for 'Flat Ceilings'. To attain an R-40 value ( RSI-7) a minimum depth of at least 16 inches (400 mm) is required.

Strapped Sloped Joist Ceiling

Strapping the ceiling is the third way of providing a good ceiling insulation level. An isolated air/vapour barrier results. This construction method utilizes 2 x 12 inch (38 x 286 mm) roof joists. At least two thirds of the insulation value must be outside the polyethylene air/vapour barrier.

No comments:

Post a Comment