Exterior Walls

This section describes types of wall construction and how walls are connected to the floor, ceiling and foundation construction to maintain airtightness and high levels of insulation. The major obstacles to well-insulated and sealed walls are the necessary penetrations in the wall such as doors, windows and electrical outlets. Again eliminating as many potential problems as possible in the design stages is the first step - place wall switches on interior partitions, locate exhaust fans on interior walls, use the most energy efficient windows and doors possible.

Since there does need to be some electrical outlets on exterior walls, they can be installed using polyethylene air/vapour boxes for wall outlets. Some of the wall details show an isolated air/vapour barrier so that electrical wiring can be installed inside the polyethylene layer. Floor or baseboard outlet systems can also be used to eliminate the problem of outlets on exterior walls.

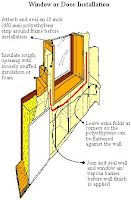

Wall Penetrations

The rough opening space left around installed doors and windows creates a special sealing and insulating problem on exterior walls. Always use good quality window and door units to minimize air leakage heat losses through the unit. They must however also be installed properly to eliminate air leakage around the units. An air/vapour barrier strip can first be sealed (caulked) and attached (stapled) around the outside of the door or window frame. Once the unit is installed the cavity between the rough opening and the window frame is then insulated. This strip is then attached and sealed to the wall air/vapour barrier to create an airtight seal around the opening.

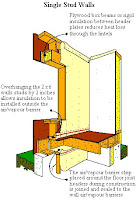

Single Stud Walls

The use of a single stud width for exterior walls is the most common form of North American residential construction. To obtain an R 20 rating (RSI 3.5) in a single stud cavity, 2 x 6 inch (38 x 140 mm) construction must be used. This is an absolute minimum wall R-value level for energy efficient housing. To maintain air/vapour barrier continuity from lower to upper floors, the polyethylene air/vapour barrier can be carried around the floor joists during the early stages of construction. If extra exterior or interior insulation is not being added the walls should be offset 2 inches (38 mm) over the edge of the subfloor so that a piece of rigid insulation can be added to the outside of the joist space (required to keep the air/vapour barrier on the inside of the insulation). Box beam lintels can be made of plywood and are one way to increase the insulation through lintels over windows and doors. Installing rigid insulation between header plates is another method.

Exterior Insulation

In an effort to provide more insulation (as well as blocking the thermal bridges through the wall studs, plates and lintels), an insulated sheathing of rigid fibreglass or rigid foam can be applied to the outside of the wall. This provides a 'blanket' over the wall with more insulation applied over lintels, double studs, corners and the joist space. As well, the sheathing layer can extend down to join the foundation covering. Window and door jamb extensions must be used when wall thicknesses are increased.

Interior Insulation

Interior strapping is another method of increasing wall insulation in single stud construction and reducing the thermal conduction through the wall studs. This method isolates the air/vapour barrier in the wall and provides a convenient cavity so that the polyethylene is not punctured for wiring or plumbing. Strapping is placed horizontally across the wall studs which works well with horizontal wallboard application. The wall air/vapour barrier must be sealed to the ceiling (or second floor), floor and foundation polyethylene layers as shown. At least two-thirds of the insulation must be outside the polyethylene air/vapour barrier.

Staggered Stud Walls

A method of increasing wall insulation levels in a single cavity is to use wider plates. Since wide studs would create more of a thermal bridge, a staggered stud wall can be used instead. A good example would be using 2 x 4 inch studs (38 x 89 mm) on 2 x 8 inch plates ( 38 x 184 mm) to create an R 28 (RSI-5) wall. Even wider plates can be used to obtain higher RSI-values. A staggered stud wall does offer benefits in terms of joist space for insulation, but the air/vapour barrier is on the inside where it can be easily damaged.

Double Wall Technique

This wall construction method was developed both to provide a wide wall cavity for high levels of insulation and so the air/vapour barrier could be isolated inside the assembly in a protected position. Two individual stud walls are constructed. The inside one, usually 2 x 4 inch (38 x 89 mm), is the structural wall and is complete with double plates, window lintels and outside sheathing. The air/vapour barrier is placed under the outside sheathing on the outside of this structural wall.

A second stud wall is placed some distance out from the structural wall - its function to provide support for the exterior finishing material. Insulation is placed in the resultant three cavities. The amount of insulation depends on the width of each cavity but there must be at least two-thirds of the total wall insulation value outside the sheathing (so that the air/vapour barrier is in the correct position).

Plywood spacers at the plates can be used to position the outer wall. If a 4 inch (100mm) cavity is left between two 2 x 4 inch (38 x 89mm) stud walls, then three layers of R-12 (RSI 2.1) insulation can be used to give a total value of R-36 (RSI 6.3). Leaving 6 inches (150mm) between the walls would result in R-44 value (RSI-7.7) being the wall total - with R-32 (RSI 5.6) on the outside of the polyethylene layer.

The double wall construction method will result in a home that is super insulated and sealed The single biggest disadvantage for double wall construction is the associated cost increase in materials and labour.

Wall Systems

A variety of wall systems are now widely available which utilize expanded-polystyrene panels combined with wood, steel or concrete structural members. Most of these wall systems derive their structural strength from integral wood or steel framing members embedded inside the insulation panels. These systems use factory built wall sections ready to be erected on site, and are available in R-20 to R-40 (RSI 3.5 to 7.0) values. Comparable roof panels are available up to R-40 (RSI 7.0). Foundation wall panels are also available which use preserved wood and sheathing or steel instead of regular wood as the structural members. A number of manufacturers offer concrete (block type) wall systems for both foundation and above grade walls with rigid insulation inserts.

Engineered structural sandwich panels (often called stressed-skin panels) are also available from a number of manufacturers. Panels generally have a pre-finished interior and exterior membrane enclosing a urethane, polystyrene or other foam core. The skins are typically made of oriented strand board (OSB), wafer board or plywood and some are available with interior surfaces pre-drywalled. Standard wall panels are available in R-20 to R-40 ( RSI 3.5 to 7.0) with roof panels up to R-60 (RSI 10.5).

No comments:

Post a Comment